Detail Clean Room System(2)

- Clasificación:Centro de Conocimiento

- Autor:Marya

- Fuente:original

- Tiempo de emisión:2021-04-27 14:53

- Visitas:

[Descripción resumida]

Detail Clean Room System(2)

[Descripción resumida]

- Clasificación:Centro de Conocimiento

- Autor:Marya

- Fuente:original

- Tiempo de emisión:2021-04-27 14:53

- Visitas:

Ⅵ.Flooring ————————————————————————————————————————————————

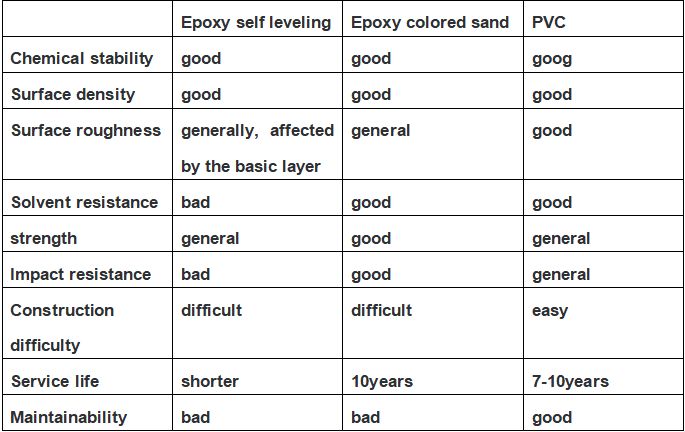

According to different user needs, we can provide epoxy self-leveling, PVC coil and epoxy colored sand floor and other different kinds of materials. Special floor materials with antistatic surfaces can be provided, and different clean levels of floor can be designed for different colors in a project.

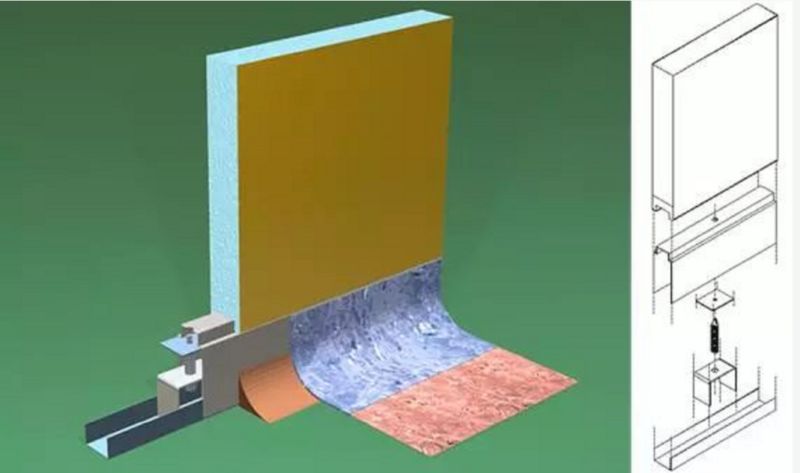

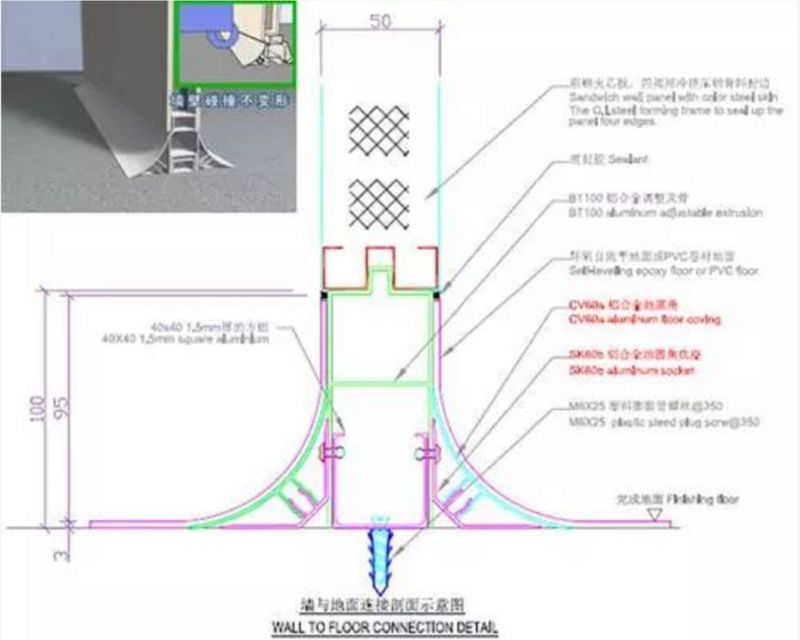

PVC, epoxy colored sand or epoxy artesian floor and wall panels connection.

►Three kinds of ground material

VII、Connector ——————————————————————————————————————————————

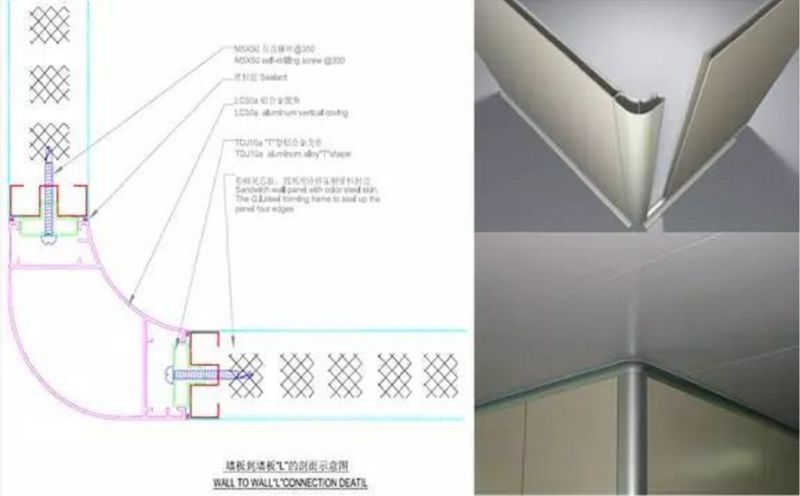

Aluminum alloy world rail profiles, other aluminum alloy profiles, 1/4 arc aluminum alloy profiles, 1/8 arc aluminum alloy die-casting parts and other auxiliary materials.

►Cleanroom aluminum profile and others

1. Material- aluminum alloy extruded profiles and aluminum alloy die casting parts.

2.Surface treatment - the aluminum alloy profile is anodized surface treatment, except for the aluminum alloy profile without exposure;

3.Material Thickness - Most aluminum profiles are 1.2mm thick, with high strength, precision dimensions and easy installation.

4.The arc radius of the rounded corner - the arc material is made of PVC and aluminum alloy material, or cross collocation, which meets the requirements of GMP and is easy to clean.

5.Sealant - Dow Corning white silica gel is used to seal the gap between the plate and a variety of gaps between the plate and the fillet. Black Dow Corning silicone is used to seal the gap between the plate and the window.

6.Sanitary aluminum parts: easy to clean, used for horizontal and vertical direction of color plate convex Angle connection. The concave edging installed at the corner is completely flat with the wall, beautiful and generous, convenient and sanitary.

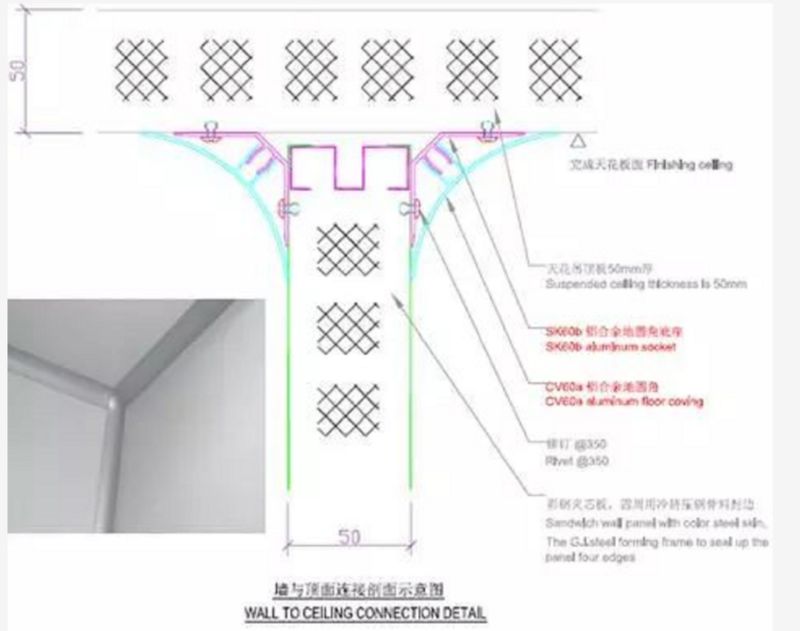

►Wall and floor connection diagram

Unique keel form, to ensure that PVC or epoxy color sand surface connect the wall up t 100mm, and completely flush with the wall, to ensure that the clean room is completely airtight, easy to clean, fully in line with GMP requirements.

►Wall connected to the ceiling of the diagram

The completely independent lifting ceiling system not only ensures the ceiling strength, but also ensures the flexible disassembly of all walls.

►Schematic diagram of wall to wall "L" connection

►Accessory

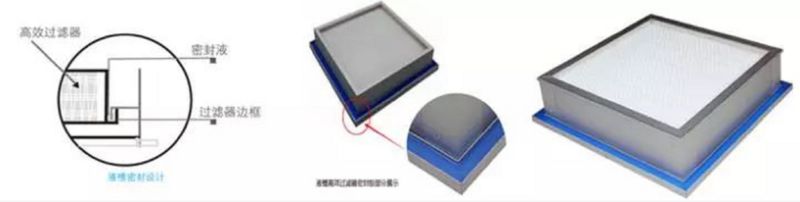

The WHO recommended swirling diffusing plate, which is good for removing corners in rooms. Selection of liquid tank sealing HEPA filter, to ensure zero leakage, to meet PAO test requirements.

►Clean cameras

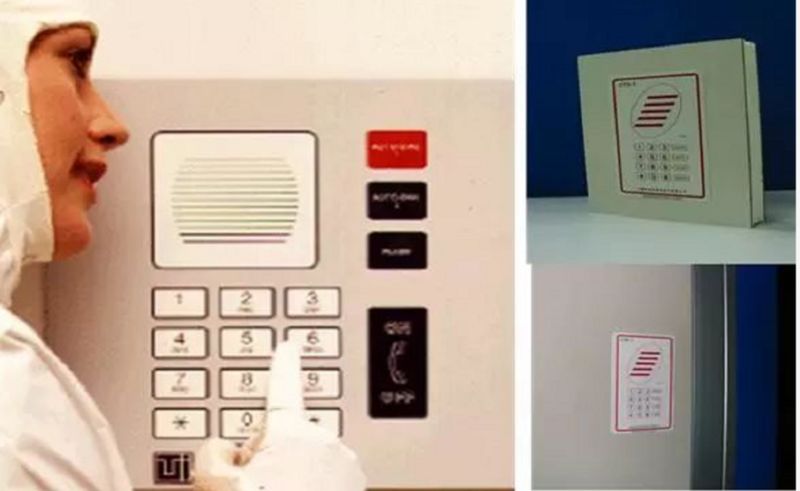

Clean telephone and wall flat installation surface can be cleaned and sterilized.

The stainless steel sheath of the micro differential pressure gauge keeps clean after disassembly, which is convenient for meter calibration.

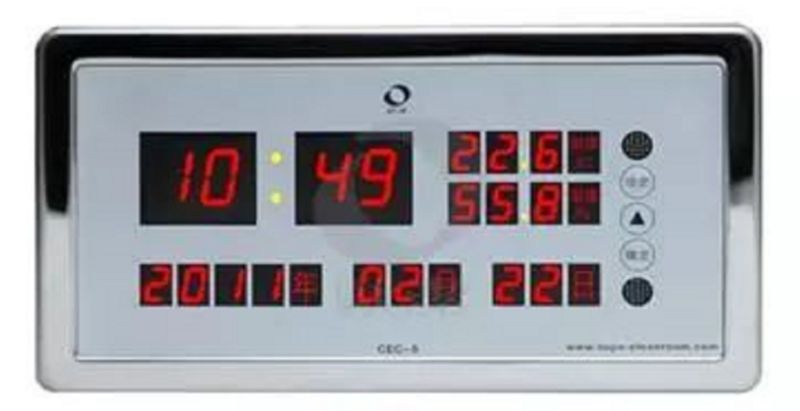

►Clean electronic clock

►Negative pressure weighing cover or laminar flow facilities

The negative pressure weighing cover ensures that the weighing process of ingredients is safe and reliable, and there is no need to worry about cross contamination. The design and use of the uniform flow film with high efficiency ensures that the wind speed in the A-class zone is uniform, within the range of 0.45m/s plus or minus 20%, in line with the requirements of FDA and EU cGMP.

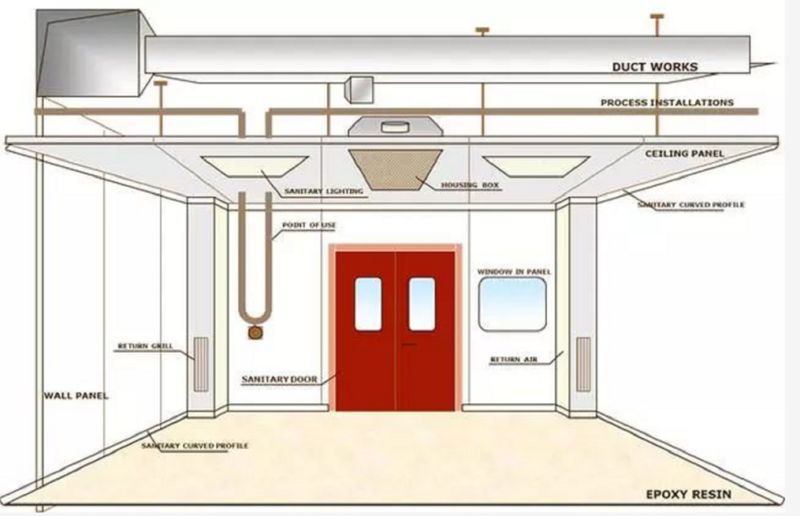

VIII、Clean room enclosure —————————————————————————————————————————

►Plan review - confirm the design standard

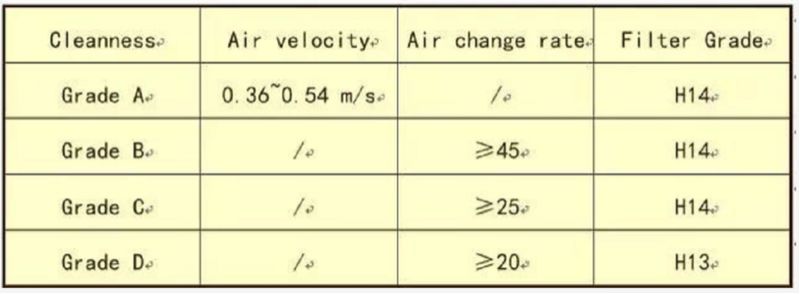

Clean air conditioning - wind speed, ventilation times, filter:

►Audit efficient arrangement and air distribution

►HVAC

IX、 Design key points - air purification ————————————————————————————————————

1. Filtering; 2. Sterilization; 3. Common purification equipment; 4. Sealing treatment of filter; 5. Ventilation times and sectional wind speed.

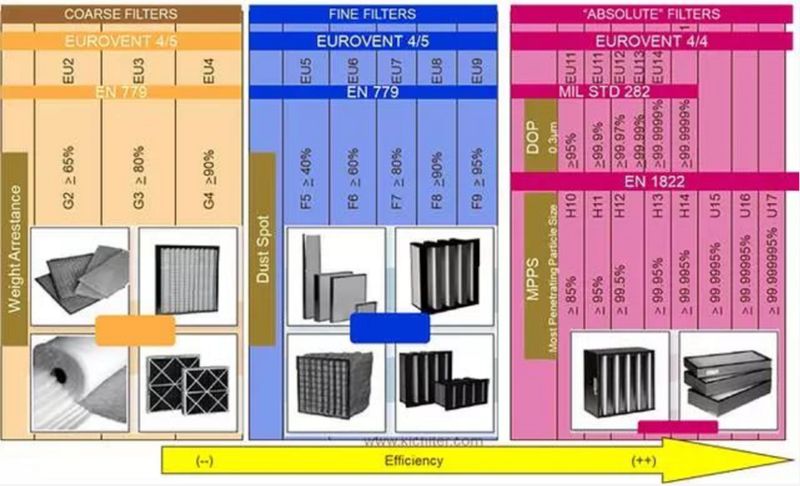

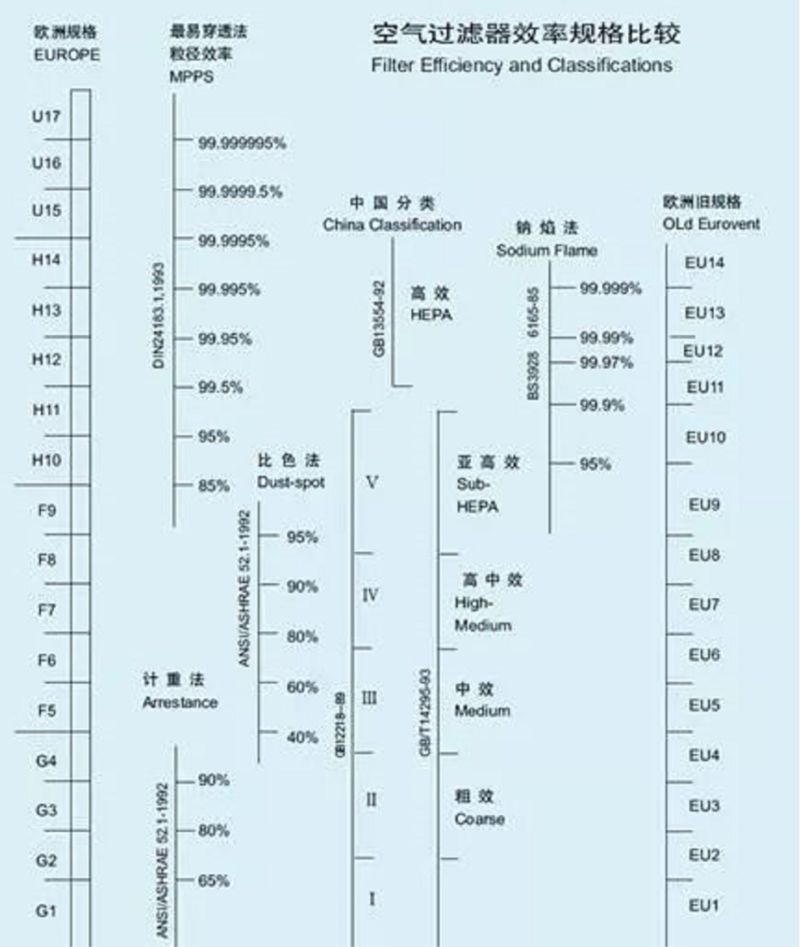

►Filtration

It refers to the selection of qualified substances from the existing batch of substances, remove the other part of substances that do not meet the conditions. Air filtration sieves out clean air to remove dust particles. The device used to filter air is an air filter.

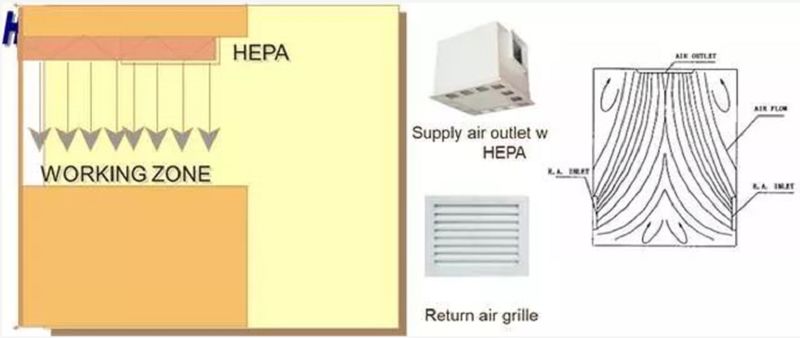

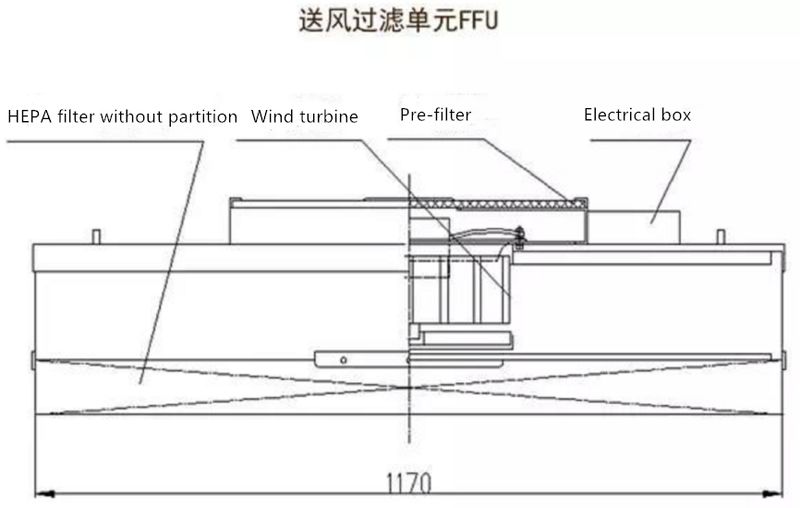

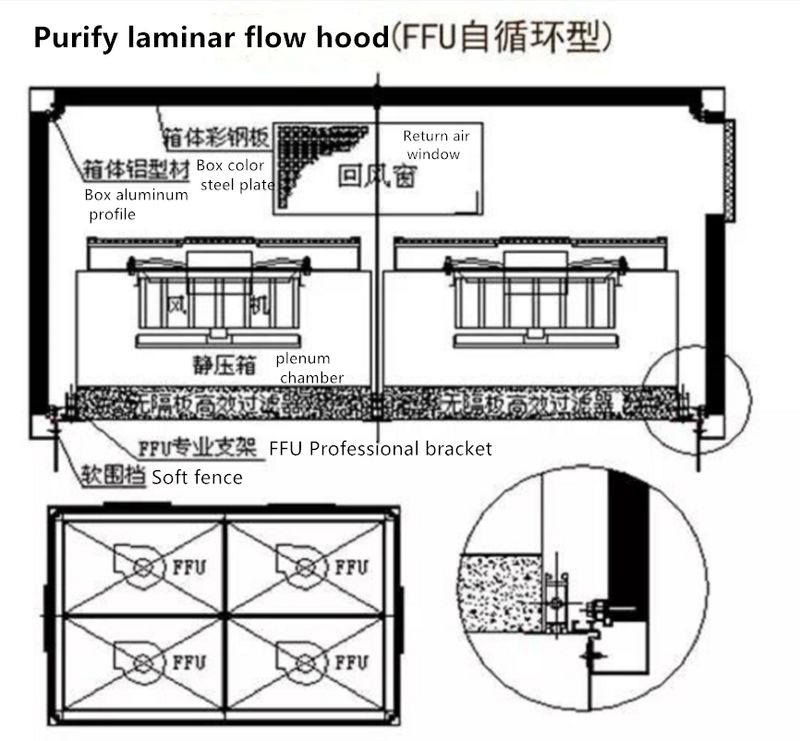

►Air supply filter unit FFU

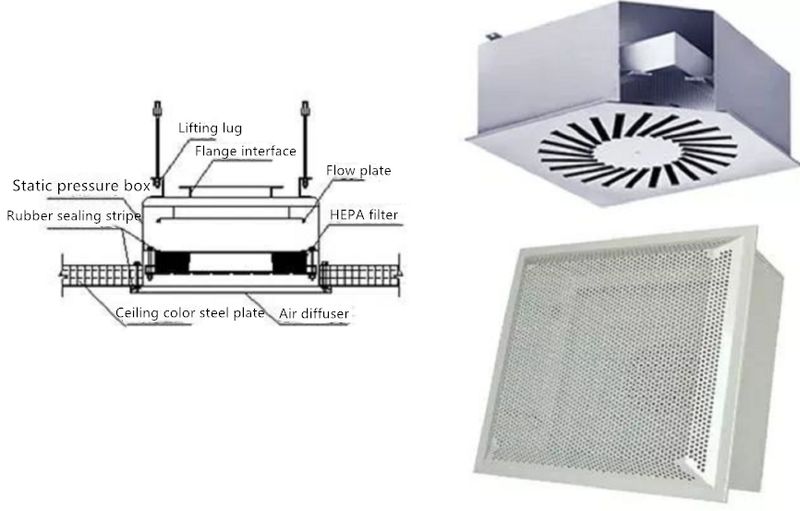

►HEPA diffuser

The lower part of the plenum is equipped with an air volume adjusting button, which can be directly adjusted below.

►Filter seal processing

The installation and sealing of HEPA filter is the key to air purification, and it is also a difficult point for a long time. Filter leak testing is the most difficult to pass the test after installation, many clean room is not successful because of the seal is not good. Even if cleanliness standards, the leak may not be up to standard. This may not be a big problem in other clean rooms, but in the pharmaceutical industry biological clean room leakage means bacteria, so sealing is the key of the key for biological clean rooms.

►At present, the commonly used sealing methods are

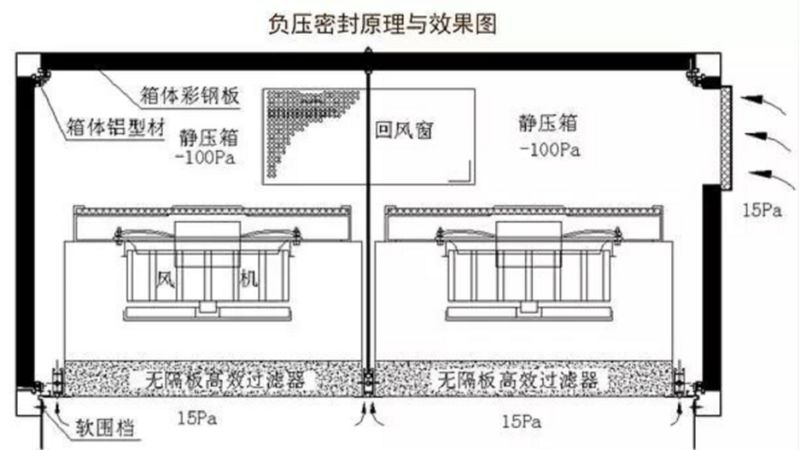

1. Negative pressure sealing: the best effect. FFU is a typical example of this.

2.Mechanical compaction: the effect is general. There are many efficient air supply outlets.

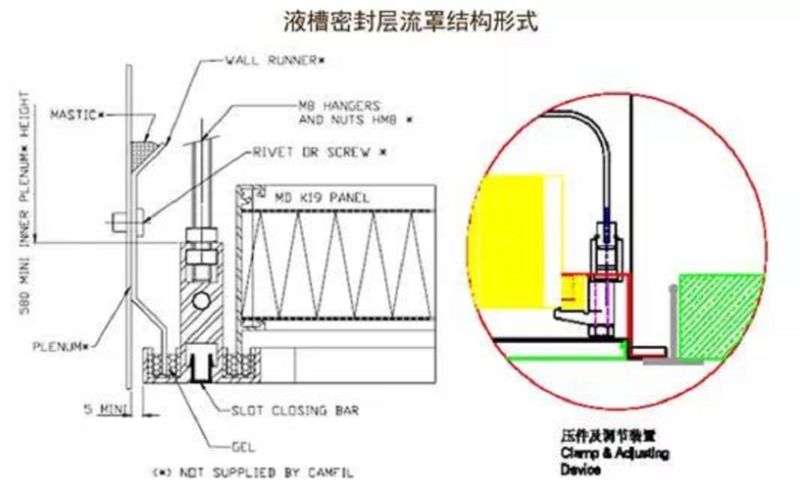

3. Liquid tank seal: the effect is very good, but the construction is difficult. The sealing effect is often affected by construction.

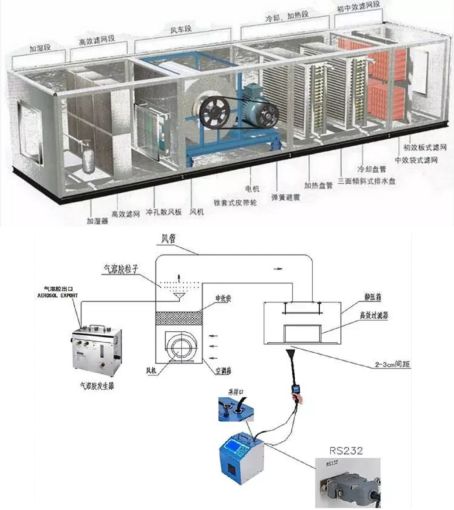

►Air-conditioning ventilation systems, air handling unit

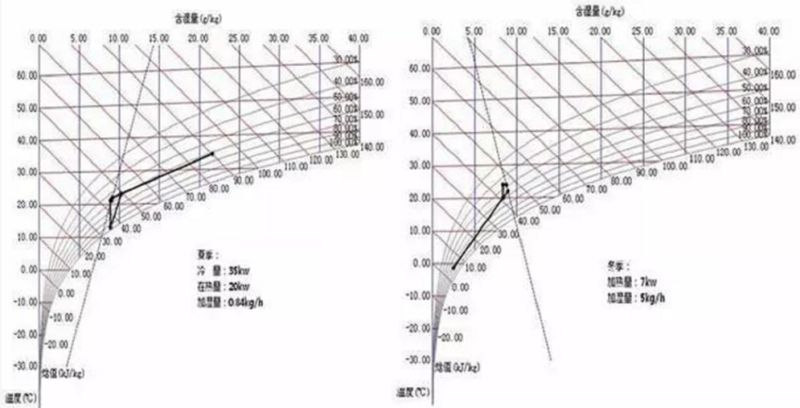

►Air handling units, air conditioning capacity calculation

Calculate the cooling capacity, heat and humidification of air conditioning according to the enthalpy and humidity chart of air volume and indoor load.

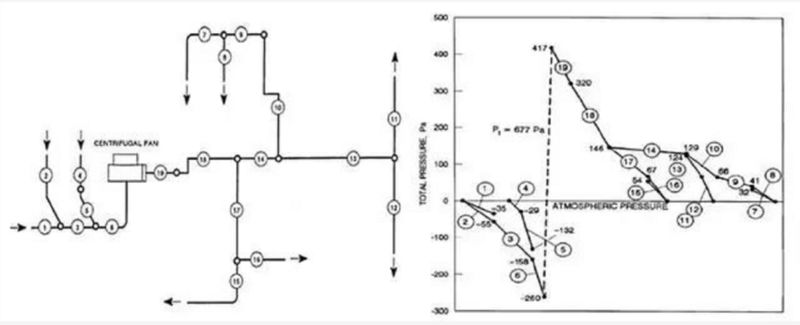

►Pipeline resistance calculation

The fan pressure is determined by the sum of pipe resistance, filter resistance and equipment resistance.

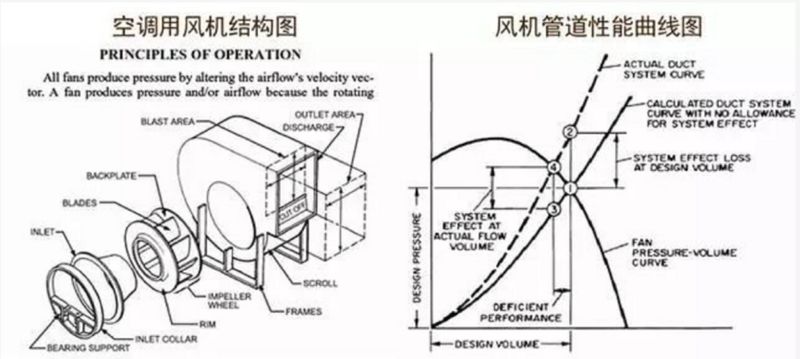

►Type selection of fan

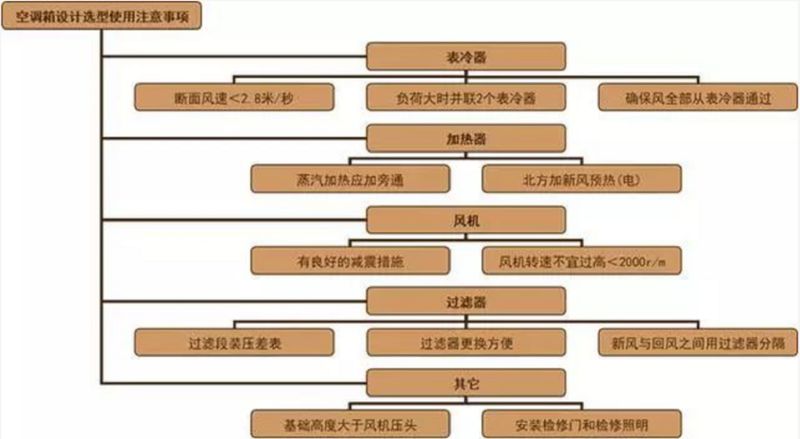

►Matters needing attention of design type selection of air handling unit

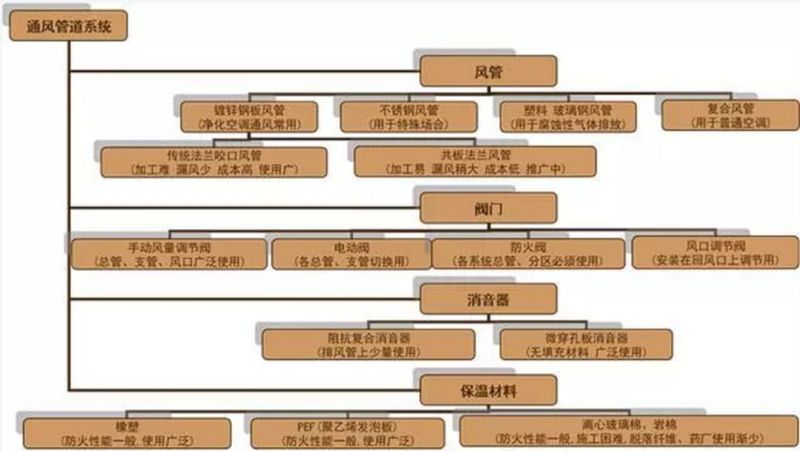

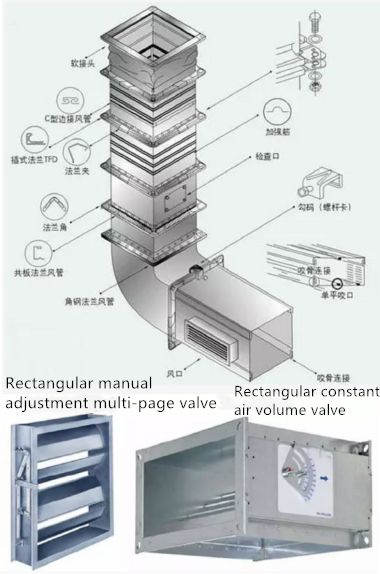

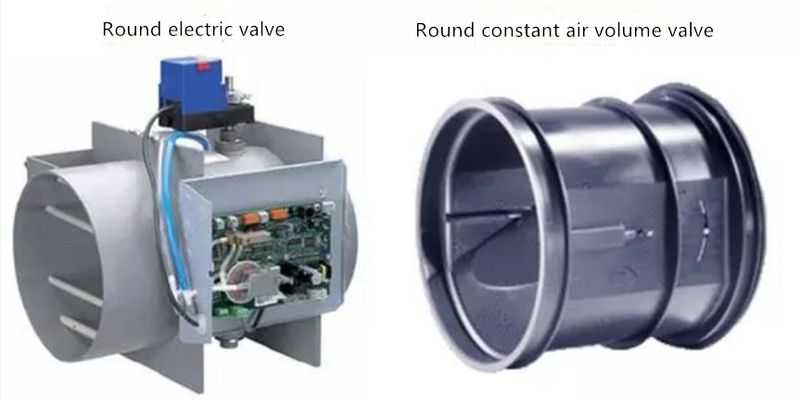

►Air-conditioning ventilation system, ventilation pipe

►Air conduit

►Air duct installation

1.Adopt high quality galvanized steel plate, on-site installation, production workshop closed and dust-free;

2.Before processing, galvanized sheet is cleaned with neutral detergent, wiped and dried before use;

3.The air duct shall not have transverse joints, and the longitudinal joints shall be minimized as far as possible. The galvanized steel plate air duct shall be processed to avoid damaging the galvanized layer;

4.After the air duct is closed, it is necessary to seal both ends with plastic cloth and put them in the clean protective shed or workshop. After the installation, the air duct is removed from the site and cleaned again before the installation.

5.According to the requirements of the design and construction drawings and the measured size on site, the processing sketch is drawn and then the system is processed, manufactured and installed one by one.

If you want to know more about cleanroom project, please click this link https://www.marya.com.cn/product/Clean-Room-Project-86.html

Contacto

Shanghai Office: No. 211 fute North Road, Pudong New Area, Shanghai, China

Changsha office: 23069 Building 6, futi xingguang Tiandi, Yuhua District, Changsha City, Hunan Province

Factory 1: Hunan Maya INTELLIGENT TECHNOLOGY Co., Ltd.

Dirección: No.3 Industrial Park No.7 Factory, Sany Road, Free Trade Zone, Changsha, Hunan, China

Factory 2: No. 555, yupan Road, weitang Town, XiangCheng District, Suzhou City, Jiangsu Province, China

Factory 3: Suzhou Industrial Park yanghe Road Venture Capital Industrial Plaza 15 - a

Teléfono: +86-13507449007

Buzón de correo:info@marya.com.cn

Buscar

Copyright © 2020 Shanghai Marya Pharmaceutical Equipment CO., Ltd. 沪ICP备11038675号-4

- +86-13507449007

- Buzón

- 返回顶部